Overview of Production Strengths #

TAI SAM CORPORATION demonstrates robust manufacturing capabilities in the production of cabinet locks and hinges. With a daily output capacity reaching up to 30,000 pieces, the company maintains high standards in both quality and efficiency. Key performance indicators include an on-time R&D sample delivery rate of at least 96.45%, a mass production yield rate of 99.83% or higher, a process yield rate above 99%, and a finished product delivery rate of at least 98.95%. Continuous process improvements are implemented to further enhance quality and reduce lead times.

Core Manufacturing Processes #

Zinc Alloy Die Casting Production Line #

The die casting process utilizes automatic machinery and a centrally controlled, fully automated furnace to ensure consistent zinc alloy temperatures. This approach effectively prevents air pockets in die castings, resulting in strong, reliable products and improved production efficiency. The facility operates dozens of die-casting machines, each equipped with automatic feeders to maintain stable material input.

Automatic Die Casting Feeders #

Consistent temperature control of zinc alloy materials is achieved through automatic feeders, which help avoid air holes in auxiliary parts and ensure the stability and strength of finished products.

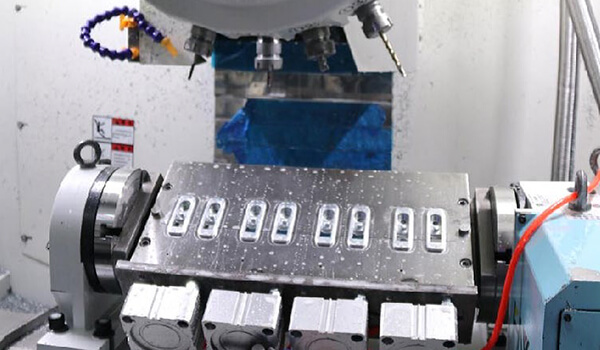

CNC Processing and Vertical Machining #

All NC processing, including mold development and sample production, is handled in-house. This direct approach eliminates communication issues and delivery delays often associated with outsourcing. The engineering team is equipped to optimize manufacturing processes, and the factory has developed its own double-sided automatic flip fixture to efficiently remove rough edges from die-cast parts.

Stamping and Plastic Injection #

The facility is equipped with advanced stamping and plastic injection machines, supporting a wide range of product requirements and ensuring flexibility in manufacturing.

Surface Treatment and Nanometer Spray Technology #

Automatic Paint Spraying Line #

The factory features a fully automatic paint spraying line, capable of handling both standard and custom surface treatments. High-resistance salt spray surface treatments are available, with salt spray tests reaching 240 to 720 hours, meeting the requirements for outdoor equipment. Powder coating and custom color or thickness options are also provided to meet diverse customer needs.

Nanometer Spray Painting #

Nanometer spraying applies nano-technology to create a fine, durable coating on product surfaces. This method offers high surface hardness, excellent corrosion resistance, and a variety of color and luster options. The process is environmentally friendly, economical, and ensures long-lasting durability. The nanometer coating excels in resistance to acid, salt, and alkali, maintaining high surface stability and hardness.

About TAI SAM CORPORATION #

TAI SAM CORPORATION has been a leading manufacturer of latches in Taiwan for over 20 years. The product range includes door latches, industrial hinges, lid stays, multi-point latching systems, leveling glides, slides, seal gaskets, pulls, handles, hand wheel knobs, clamps, safety latches, casters, and inside release handles. The company is committed to innovation and strict quality control, offering high-quality products, competitive pricing, and prompt delivery. TAI SAM also provides professional design support, 3D file downloads, unlimited minimum order quantities, free samples, and technical information to support customer needs.